If you wheel your rig, the underside is going to take hits. The tailpipe on the 80 series, and on the predecessor 60 series, exit in an exposed spot under the rear bumper. In my 1982 FJ60, I kept a breaker bar handy to pry the tailpipe back open. I never had that problem in my 80 because I hit the tailpipe so badly the first year I owned it, 2002, that we had to cut it off on the trail. (My trail kit includes a hacksaw.). Rolling backward down the “wall” in Poughkeepsie Gulch, in the San Juan mountains of Colorado, the tailpipe and resonator caught the ground and pretzeled up under the body. Driving back home across Colorado the hot exhaust gas melted a mud flap and bumperette. More clearance!

More than once, but surprisingly few times, I hit the muffler on a rock. Whatever's inside the muffler loosened and would rattle at specific RPMs. I tolerated the rattling and whistling exhaust since it only occurred at specific RPMs and the stereo drowned out the noise. At least twice I replaced the rubber mounts, which do a fine job if you don't use them to support the truck on a rock. Recently I found the muffler bracket had cracked off. If not for plenty of trail time, there would have been nothing wrong with the exhaust. The Toyota Land Cruiser exhaust is stainless steel built to withstand harsh treatment and high miles.

Recently I had been eyeballing replacing my muffler and tailpipe. The OEM muffler, if you can get one, (called the “center pipe”) lists for $627.63. The tailpipefor $298.28. My local Toyota dealer showed five tailpipes and three mufflers available in the US.

I approach the aftermarket with caution. Usually the upfront cost savings or “improved design” is lost over the long lifespan of these trucks. Last time I bought aftermarket was a well-regarded brand high-pressure power steering line. It lasted two years. The original OEM made from 409 stainless steel had lasted 19. Most people consider five, six, or 10 years an acceptable lifespan. We don’ t.

We met the folks from Borla Performance Industries, Inc., Johnson City, Tennessee, at Overland Expo back in 2015. A major provider of aftermarket and racing performance exhausts, Borla was actively engaging the 4 x 4 and Offroad community. We wanted to learn more about their offerings. Questions started flying. Borla offers Cat-Back™models for the Tacoma, Tundra, FJ Cruiser, and Land Cruiser. They wanted to provide us with a system to install and test. We wondered if we’ d put their “million mile” warranty to the test.

While we always initially like the sound of “free” product to test, the reality is very different. Like you, we rely on our gear to get us out and back. Inferior products ultimately cost more. Whether it’ s an earlier replacement, having to call a tow truck (if you can call and if a tow truck can get to you), or having a trip cut short,it’ s just not worth it. But, how would their product fit? How would it hold up? Here's what we know from installation, 90 days, and 800 miles off-road.

First, we had to select a product. The Toyota Land Cruiser 80 series was offered in the US as the FJ80 in 1991 and 1992 with the same engine as the predecessor FJ62. 1993 saw the introduction of the FZJ80 with the new 1FZFE 4.5 liter inline six engine, rear disc brakes, an option for full floating rear axle, and front and rear factory electronic locking differentials. 1995 to 1997 models are also the FZJ80 but distinguished by electronic changes with the introduction of OBDII diagnostics. There was also a side-by-side catalytic converter configuration resulting in a different muffler input and pipe routing.

Prior to selecting my exhaust system, I had several conversations with the Borla representative on finding the right product. A generic muffler, of which Borla offers many, would work and offer all three sound options but would require bending a custom tailpipe. The Cat-Back™ model developed by Borla for the 80 series is designed asa direct bolt-on for the 1995 - 1997 FZJ80 at the “touring” sound level, the quietest. The only problem, I own a ’ 93.

I examined Borla’ s drawings and specifications and consulted with several Land Cruiser parts gurus. The Borla exhaust uses 2.25” 304 stainless steel. The 1993 – 1997 models use an identical tailpipe. The Borla drawings looked right. The muffler size and rear mount are also identical across the years. We expected these would work on my ‘ 93.

However, the muffler input and location of the rear O2 sensor is different over the model years. The 1993 – 1994 Land Cruiser has an O2 sensor forward of each catalytic converter. The catalytic converters are in a side-by-side configuration in a single heat shield. The 1995 – 1997 models have an O2 sensor before and after the two in-line catalytic converters. The Borla muffler comes with a bung for the rear sensor welded to the input pipe, OEM style. The pipe between the muffler and catalytic converters goes over the frame rail in a 1993 – 1994 and under in a 1995 – 1997. Having worked out the differences, Borla recommended we start with the 95 to 97 muffler and tailpipe, Borla model 14590. MSRP is $765.99. I found various online retailers for around $690.00.

The choice of the model 14590 over a muffler and bending pipe was based on the belief that the model 14590 tailpipe would be a direct fit and the muffler was tuned to the engine common to both variants. Using the 95-97 system should only require modification of the muffler input.

For installation, I turned to my local resources in the Rising Sun Four Wheel Drive Club of Colorado. I was connected with AA Performance Muffler and Brake, nearby in Englewood (www.aaperformancemuffler.com). Favorites with the 4 x 4 community and well-known for custom exhaust work, Scott and Tammy were happy to work with me knowing that I'd be crawling around under the truck with them taking photographs and asking questions.

The exhaust arrived via Fed Ex ground securely packaged in expansive foam. Despite its size, the 70” long, 43-pound box was easy to handle. Given the busy life for all, the Borla box sat in my garage for several months before installation.

The first thing we did was evaluate the muffler, tailpipe, and hardware. The Borla came with all the necessary gaskets and hardware. We placed each up next to the truck for fit and comparison.

Out came the Sawzall and before I could get the camera ready my old muffler and tailpipe was on the floor. Still, it did not give up without a fight. The tough Toyota stainless steel required fresh blades.

Next, Scott and fabricator, Tory got to work cutting back the input pipe on the new muffler. When they were done a short section of straight pipe remained to stick out from the muffler. They mocked up the new exhaust in place and located it using the factory rear mount – which lined up perfectly with the Borla. They supported the front of the muffler on shop-fabricated fit and weld stands. Then they cut, flared, and slipped a short section of straight pipe over the stub extending back from the catalytic converter flange to the stop coming out of the new muffler.

One option would have been to cut the flange off the output of the catalytic converters. I requested they retain the flange so I would have bolt on capability for catalytic converters. I did not replace the catalytic converters because even with 280,000 miles they just recently passed emissions and my next test wasn't coming for two more years. Now if I need to replace the catalytic converter's it will be a bolt on, OEM style.

Once tacked in place, the new pipes were fully welded in place. After each weld they used a mirror attached on a stick, also fabricated in the shop, to check welds and verify there would not be any leaks.

Quickly it was time to go to the tailpipe. For a mostly on road rig the exhaust will exit in the OEM location under the rear bumper. Some, including me, had my trail-clearance exhaust exiting under the body. Tucked out of the way, and pointing down. I had no ill effect. But it’ s unwise to have the exhaust exit under your truck. Hot gases melt things. Exhaust moisture rusts things. Air pressure can suck the exhaust into the cab –a potentially fatal situation. If ever stopped in an area where exhaust could accumulate under the truck, say perhaps in deep snow, running the engine could be fatal.

Related Articles

The Borla comes with a resonator in the OEM style. Without a resonator, some people experience exhaust whine or whistle. Some find it objectionable and others don't notice. We thought about reattaching the resonator - there is plenty of room. Ultimately we deleted it.

Most aftermarket exhausts are going to mimic OEM routing. This was no exception. However, knowing that I did not want the OEM tailpipe exit for my extensive off-road use, we planned to cut off the resonator and have the tailpipe exit at a45-degree angle behind the rear passenger tire. That turned out well. I’ m only regretting that we did not complete the installation first to hear how it sounded with the resonator. However, earlier in the year at Cruise Moab I listened to a Borla exhaust installed on another 80 Series that still had its resonator. It was very quiet. Just like I wanted.

Toyota put early Land Cruiser exhausts in a protected spot exiting behind the rear tire. Duplicating this location would also allow a bit of bling with the Borla chrome tip peeking out. The tip is vented and could also save you a leg burn. Fitting the tip was as simple as holding it in the desired location while Scott and his crew eyeballed a length of pipe needed. They bench welded the tip onto the pipe and tacked the pipe and tip in place, confirming location with me before final weld. My location would interfere with the stock bumperette. If I had them I would either have to trim some plastic or angle the tip downward slightly.

The final step was a new exhaust hanger at the tailpipe. Though the Toyota stock units are quite stout I'm confident this generic version is going to last a very long time. To mount it, Scott and Tory first unbolted the stock rear hanger bracket. Then they welded a bolt to the inside of the frame and fastened the hanger to it with two nuts. We were done.

The first thing I noticed when we fired it up was how quiet it was. This exhaust is the “touring” sound, Borla’ s quietest model. As much as I wanted to sound like the Canguro Baja 1000 race truck, I said a thank you to Scott, Tammy, and the crew settled up my installation tab and drove quietly off on the streets of Denver.

The rattle was gone and everything seemed smoother. The differences were more noticeable as I put on more street miles. I was glad the rattle had been in my muffler and not the catalytic converters.

Before long I started to notice a noise that sounded like the exhaust hitting the frame. It would happen only at 1500 RPMs and only under load. Never while revving the engine in park or neutral. It was mild and I actually forgot about it for a while.

A few weeks later I headed out to lead the Denver trail run to CruiserFest in Salt Lake City. We were about to cover an estimated 750 miles of dirt. The 1500 RPM rattle under load was still there. I was noticing it more since I was spending more time in the saddle.

The first morning on the trail was a crisp and clear camp at 9,000 feet on Buffalo Pass in north-central Colorado. Ascending to the 10,295 ft summit, my first thought was that I no longer had exhaust noise. Now I had an exhaust “sound.” The engine was singing a tune as I eased on and off the throttle while ascending the smooth dirt. The notes were telling me things were happening. I was playing the tune with RPM, speed, throttle, gear, and load. I was digging it.

We didn't have much challenging four-wheeling and no rock crawling, but at no time did I worry about hitting the exhaust. My garage measurements before and after installation show a half inch clearance gain measured from the lowest part of the muffler. The Borla muffler is smaller than OEM. While it's oval design sits vertically, it does not reach any lower. Here Borla could maximize ground clearance by rotating the muffler to the horizontal. A good fabricator should be able to do that for you with relative ease. Further, based on my experiences of catching the leading edge of the muffler on rocks, I plan to go back to the shop and rotate the muffler or weld a small ramp to the front.

On our very last day approaching Salt Lake City I climbed underneath and see if I could determine where the exhaust was hitting. The shiny spot was where my transmission skid plate mount was very close to the factory pipe just after the catalytic converters. Thenew installation probably moved the existing pipe about a quarter inch which was just enough. Further 12+ years of hitting that skid plate had caused its mount to bend slightly, putting it even closer to the exhaust. The immediate solution was to loosen the skid plate mount bolts, which also hold the slider in place, and slide the plate down the frame about a quarter inch. That helped somewhat but a more permanent solution will be needed. I can't blame Borla for this. Not every aftermarket skid plate or slider situation can be anticipated.

In sum, the Borla is a competitively priced product with good fit and finish and I'm looking forward to many happy years of listening to its music.

[flickr set=72157675300368874]

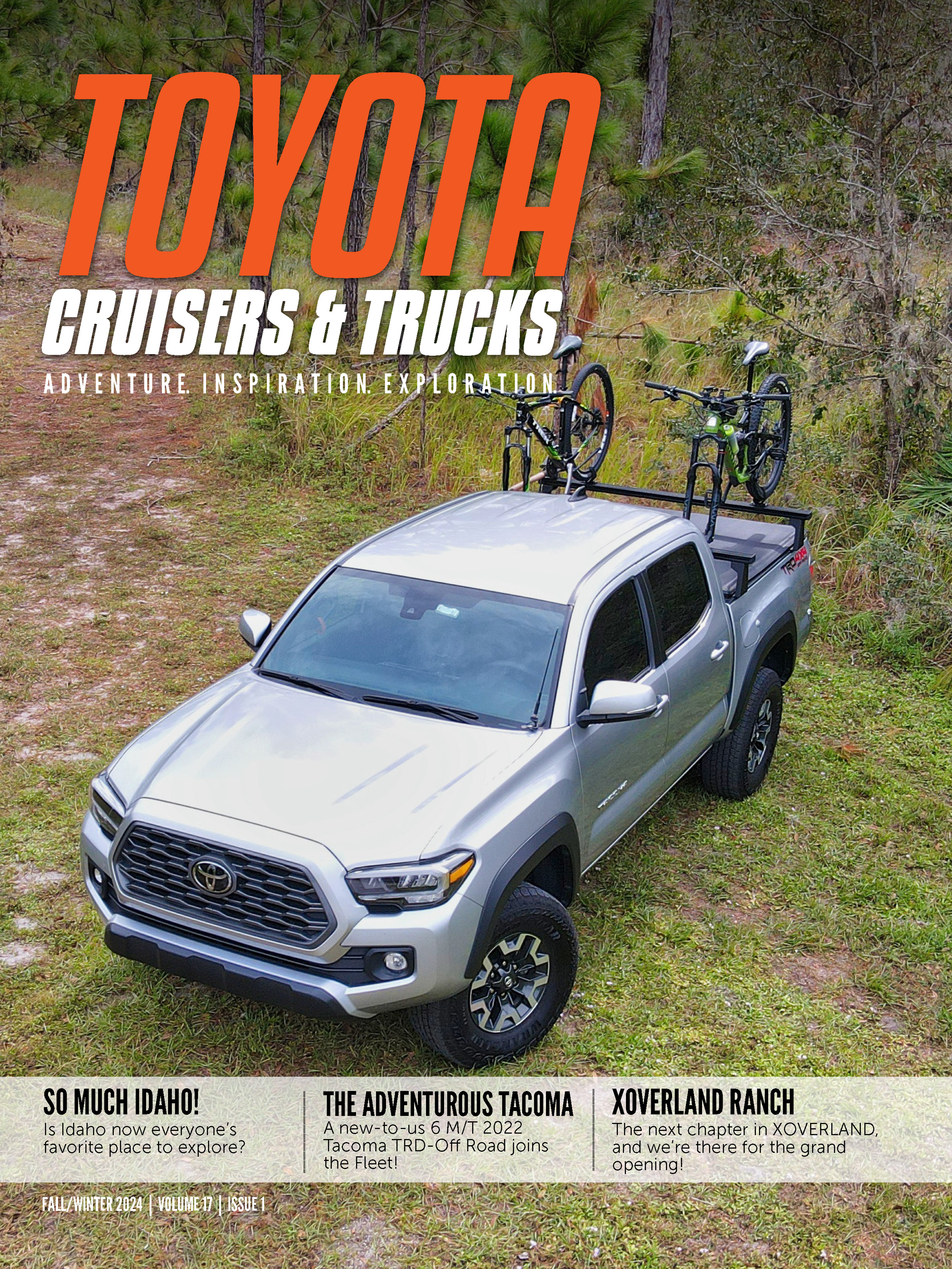

To get your copy of the

Fall 2016 Issue: